We found 188 price guide item(s) matching your search

There are 188 lots that match your search criteria. Subscribe now to get instant access to the full price guide service.

Click here to subscribe- List

- Grid

-

188 item(s)/page

A WILLIAM IV SILVER FIDDLE PATTERN CADDY SPOON, maker probably George Wintle, London 1827, the shaped bowl with wriggle engraved flower, 4" long, together with a pair of bright cut engraved sugar tongs, London 1796, and a pair of later "andiron" tongs, Sheffield 1911, 2ozs 4dwts total (3) (Est. plus 21% premium inc. VAT)No splits or engraving to spoon but a little mis-shapen. Georgian tongs not engraved, generally good. "Repro" andiron tongs good

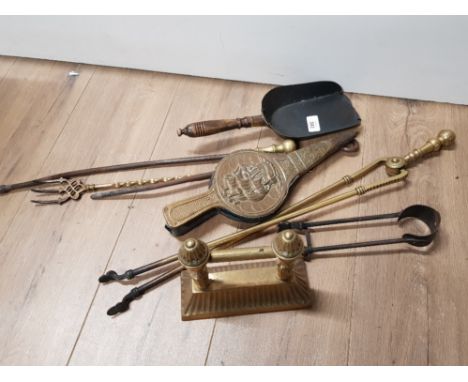

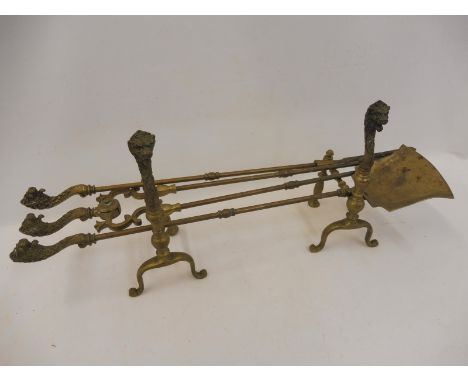

A Victorian style gilt metal chenet with adjustable central panel, height 45cm, width 140cm.Additional InformationGeneral wear, rust/blue corrosion colour to the body and rims of each piece, general wear, minor pitting, one screw bolt is missing from the back of the plate. Depth of andiron 10cm.

A brass fire screen with swag detail and a similar fender (2). Fender measures 14cm tall 83cm wide, andirons measure 54cm tall and 26cm wide.Additional InformationFender has a central part missing, stamped PCCF to verso, general surface wear scratches tarnishing throughout, loose parts to joints on fire screen and andirons, one andiron with corner bent so it doesn't stand properly. Appears late 19th or early 20th century.

‡A pair of Art Deco patinated bronze owl andirons attributed to Edgar Brandt (French 1880-1960), each in the form of a horned owl perching on a pair of entwined snakes, on an inverted breakfront plinth, (struts lacking), 52.5cm high, 35.7cm wide. (2) Provenance: The Collection of Sir Jeremy Lever. For similar examples see: Sotheby's, New York, 6th December 1996, lot 304. A single, signed, unmounted version of this andiron sold at Sotheby's, Monte Carlo, 11th March 1984, lot 343. A similar pair sold at Neal Auction Company, New Orleans, 21st April 2012, lot 545.

A pair of 16th century Gothic Andirons, the capped pillars with hatched decoration, a shield initialled IHS, on gothic arched feet 43 x 25 x 43cm (17 x 10 x 17in) Literature: Shuffrey (L.A), The English Fireplace and Its Accessories, published by Batsford, 1912, p.133, fig.126, Godlington, Kent Notes:Dr Brian Gilmour PhD, Dip Cons, FSA, FCIFA, FRMS, Archaeometallurgy and Archaeology, 20, Squitchey Lane, Oxford OX2 7LB Tel: 01865 552294 Mob: 0776 233 8189 Email: bjjg1243@gmail.com Early metalworking: Technology, analysis and appraisal Work carried out: Detailed assessment Report no: 560 Artefact type/description: Pair of andirons Reference no: RC1 Estimated stylistic date: c 16/17th century AD Report for: Richard Crowther Date: 09-06-2018 Assessment result/recommendation: Acceptance as 16th/17th century Report: See below Introduction, description and preliminary assessment: Fig. 1: Front view of this distinctive pair of andirons The front part of this pair of heavy cast iron andirons consisted in each case of an upper column with a capital of curly ionic form, the rectangular-section columns having diagonal reeded decoration below which was a form of shield with Gothic lettering – possibly IM – on either side of which projected two solid, curved, rectangular section Gothic style feet (fig. 1). The surface of each andiron had a pitted and worn appearance consistent with probable long use. Height: 28cms Depth (front to back): 43cm Analytical examination by metallography: A small sample was taken from the foot of one of the andirons and this was mounted and prepared for metallographic analysis. The aim of this was to look at the structure of the cast iron to determine whether this was consistent either with a 16th or 17th century origin as suggested by the style or a 19th century reproduction, these being the two likely alternatives. Fig. 2: View showing a ‘mottled’ cast iron structure with characteristic dark ‘rosettes’ graphite dispersed amongst a hypo-eutectic white cast iron matrix with a clear (fir tree-like) dendritic structure visible between the rosettes (scale x75 as shown here). Fig. 3: Detailed view of the same structure showing the flake structure of the graphite rosettes and the ladder-like dendrites in between (Magnification x300). Metallographic results: The structure visible in section shows that these andirons consist of ‘mottled’ cast iron, a transitional form of cast iron with a matrix which shows up as a white cast iron but which has ‘rosettes’ of graphite scattered through the structure, graphite being typical of an incipient form of grey cast iron. Thus the metal is a transitional form of cast iron with characteristics of both a white cast iron, where the carbon present has not had time to transform to graphite, and a grey cast iron where most of the carbon present has transformed to graphite during the solidification process. In white cast iron – as in the matrix here – the carbon in the metal is mostly present in chemically combined forms which make the metal much harder and more brittle. The dendritic dispersion visible is a phenomenon typical in a hypo-eutectic white cast iron, one with a carbon content between about 3.0 and 3.5%. Discussion and conclusion: When a cast iron cools and solidifies it can form either an all white cast iron structure, if the cooling rate is rapid enough, or a grey cast iron if the cooling rate is slow enough. There is a third possibility which is that it can form an intermediate ‘mottled’ form as we see in the case of these andirons, this being the consequence of an intermediate cooling rate. The cooling rate is clearly affected by the bulk volume of an iron casting and we can expect this to be more or less the same for any particular bulk of casting. The cooling rate – in terms of what type of cast iron (white or grey) results can also be affected or controlled by other elements present in the metal, such as silicon and sulphur, and these are a reflection of the cast iron production (smelting) process being used at any particular time. Smelting conditions changed during the development of the Industrial Revolution and the consequence of this is that ‘mottled’ cast iron is the most typical form of cast iron found in castings such as andirons and fire-backs of the 16th and 17th centuries. By the 19th century the smelting processes had changed and castings of this kind are almost always found to be made of grey cast ion. In the case of the andirons studied here the general appearance and worn nature of the andirons and their structure indicate them to be intact surviving examples of 16th/17th century production, probably from the Weald of the Sussex/Kent border region.

A pair of 17th century Wealden cast iron Andirons, Mayfield, Sussex, bearing the Phoenix shield below the capped and fluted columns 38 x 23 x 38cm (15 x 9 x 15in) Notes: Dr Brian Gilmour PhD, Dip Cons, FSA, FCIFA, FRMS, Archaeometallurgy and Archaeology, 20, Squitchey Lane, Oxford OX2 7LB Tel: 01865 552294 Mob: 0776 233 8189 Email: bjjg1243@gmail.com Early metalworking: Technology, analysis and appraisal Work carried out: Detailed assessment Report no: 561 Artefact type/description: Pair of andirons Reference no: RC2 Estimated stylistic date: c 16/17th century AD Report for: Richard Crowther Date: 09-06-2018 Assessment result/recommendation: Acceptance Report: See below Introduction, description and preliminary assessment: Fig. 1: Front view of this very distinctive Henry Tudor style of andiron. The form of cast decoration on the front of this pair of andirons is Henry Tudor in style. The capitals at the top of the rectangular columns is toothed in form, and the Tudor rose is capped with a crown, and lower down chalice and fleur-de-lys durations are also present, and there is a rose present on either side of the fleur-de-lys on the upper parts of the stepped legs/feet. Height: 38cm; Depth: 36cm Analytical examination by metallography: A small sample was taken from the foot of one of the andirons and this was mounted and prepared for metallographic analysis. The aim of this was to look at the structure of the cast iron to determine whether this was consistent either with a 16th century origin as suggested by the style or a 19th century reproduction, these being the two likely alternatives. Fig. 2: View showing a ‘mottled’ cast iron structure with characteristic dark ‘rosettes’ graphite dispersed amongst a hypo-eutectic white cast iron matrix (scale x75 as shown here). Fig. 3: Detailed view of the same structure showing the dispersion of graphite rosettes through a white cast iron matrix (scale x300 as shown here) Metallographic results: The structure visible in section shows that these andirons consist of ‘mottled’ cast iron, a transitional form of cast iron with a matrix which shows up as a white cast iron but which has ‘rosettes’ of graphite scattered through the structure, graphite being typical of an incipient form of grey cast iron. Thus the metal is a transitional form of cast iron with characteristics of both a white cast iron, where the carbon present has not had time to transform to graphite, and a grey cast iron where most of the carbon present has transformed to graphite during the solidification process. In white cast iron – as in the matrix here – the carbon in the metal is mostly present in chemically combined forms which make the metal much harder and more brittle. The density of the rosettes and the appearance of the white cast iron matrix is indicative of a (hypo-eutectic) carbon content of approximately 4.0%. Discussion and conclusion: When a cast iron cools and solidifies it can form either an all white cast iron structure, if the cooling rate is rapid enough, or a grey cast iron if the cooling rate is slow enough. There is a third possibility which is that it can form an intermediate ‘mottled’ form as we see in the case of these andirons, this being the consequence of an intermediate cooling rate. The cooling rate is clearly affected by the bulk volume of an iron casting and we can expect this to be more or less the same for any particular bulk of casting. The cooling rate – in terms of what type of cast iron (white or grey) results can also be affected or controlled by other elements present in the metal, such as silicon and sulphur, and these are a reflection of the cast iron production (smelting) process being used at any particular time. Smelting conditions changed during the development of the Industrial Revolution and the consequence of this is that ‘mottled’ cast iron is the most typical form of cast iron found in castings such as andirons and fire-backs of the 16th and 17th centuries. By the 19th century the smelting processes had changed and castings of this kind are almost always found to be made of grey cast ion. In the case of the andirons studied here the general appearance and worn nature of the andirons and their style and structure indicate them to be intact surviving examples of 16th century production, probably from the Weald of the Sussex/Kent border region.

A pair of 16th century cast iron pillar Andirons, with Tudor rose & crown, goblet and fleur de lys moulded columns, on stepped feet, with later back legs (2) 38 x 25 x 38cm (15 x 10 x 15in) Provenance: Similar to those at Leeds Castle, KentLiterature: Shuffrey (L A) The English Fireplace and Its Accessories, published by Batsford, 1912, p.133, fig.127Notes: Dr Brian Gilmour PhD, Dip Cons, FSA, FCIFA, FRMS, Archaeometallurgy and Archaeology, 20, Squitchey Lane, Oxford OX2 7LB Tel: 01865 552294 Mob: 0776 233 8189 Email: bjjg1243@gmail.com Early metalworking: Technology, analysis and appraisal Work carried out: Detailed assessment Report no: 562 Artefact type/description: Pair of andirons Reference no: RC3 Estimated stylistic date: c 16/17th century AD Report for: Richard Crowther Date: 09-06-2018 Assessment result/recommendation: Acceptance as 16/17th century Report: See below Introduction, description and preliminary assessment: Fig. 1: Front view of this very distinctive Henry Tudor style of andiron. The form of cast decoration on the front of this pair of andirons is Henry Tudor in style. The capitals at the top of the rectangular columns is toothed in form, and the Tudor rose is capped with a crown, and lower down chalice and fleur-de-lys durations are also present, and there is a rose present on either side of the fleur-de-lys on the upper parts of the stepped legs/feet. Height: 37cm; Depth (front to back): 30cm. Analytical examination by metallography: A small sample was taken from the foot of one of the andirons and this was mounted and prepared for metallographic analysis. The aim of this was to look at the structure of the cast iron to determine whether this was consistent either with a 16th century origin as suggested by the style or a 19th century reproduction, these being the two likely alternatives. Fig. 2: View showing a ‘mottled’ cast iron structure with characteristic dark ‘rosettes’ graphite dispersed amongst a hypo-eutectic white cast iron matrix (scale x75 as shown here). Fig. 3: Detailed view of the same structure showing the dispersion of graphite rosettes through a white cast iron matrix (scale x300 as shown here) Metallographic results: The structure visible in section shows that these andirons consist of ‘mottled’ cast iron, a transitional form of cast iron with a matrix which shows up as a white cast iron but which has ‘rosettes’ of graphite scattered through the structure, graphite being typical of an incipient form of grey cast iron. Thus the metal is a transitional form of cast iron with characteristics of both a white cast iron, where the carbon present has not had time to transform to graphite, and a grey cast iron where most of the carbon present has transformed to graphite during the solidification process. In white cast iron – as in the matrix here – the carbon in the metal is mostly present in chemically combined forms which make the metal much harder and more brittle. The density of the rosettes and the appearance of the white cast iron matrix is indicative of a (hypo-eutectic) carbon content of approximately 4.0%. Discussion and conclusion: When a cast iron cools and solidifies it can form either an all white cast iron structure, if the cooling rate is rapid enough, or a grey cast iron if the cooling rate is slow enough. There is a third possibility which is that it can form an intermediate ‘mottled’ form as we see in the case of these andirons, this being the consequence of an intermediate cooling rate. The cooling rate is clearly affected by the bulk volume of an iron casting and we can expect this to be more or less the same for any particular bulk of casting. The cooling rate – in terms of what type of cast iron (white or grey) results can also be affected or controlled by other elements present in the metal, such as silicon and sulphur, and these are a reflection of the cast iron production (smelting) process being used at any particular time. Smelting conditions changed during the development of the Industrial Revolution and the consequence of this is that ‘mottled’ cast iron is the most typical form of cast iron found in castings such as andirons and fire-backs of the 16th and 17th centuries. By the 19th century the smelting processes had changed and castings of this kind are almost always found to be made of grey cast ion. In the case of the andirons studied here the general appearance and worn nature of the andirons and their structure indicate them to be intact surviving examples of 16th century production, probably from the Weald of the Sussex/Kent border region.

A mixed lot of silver items, various dates and makers, comprising a pair of grape scissors, by Walker and Hall, Sheffield 1890, pierced foliate handles, a pair of andiron sugar nips, a pair of sugar tongs, four salt spoons and a carved hard stone handled base metal desk seal, approx. weighable 6.5oz. (qty)

A collection of five pairs of silver sugar nips / tongs, comprising: a pair of 'Andiron' form, oval bowls with plain rat-tails, plus a pair of very small 'Andiron' tongs, and two pairs of sugar nips, with scroll arms and ring handles, and a pair of continental sugar tongs, approx. weight 3oz. (5)

-

188 item(s)/page